In the competitive landscape of modern manufacturing and logistics, efficient material handling systems are crucial for ensuring productivity and operational efficiency. Among the various solutions available, slat conveyors stand out as a reliable choice. Technolink, a prominent brand in India, specializes in providing high-quality slat conveyors that cater to the diverse needs of various industries.

What Are Slat Conveyors?

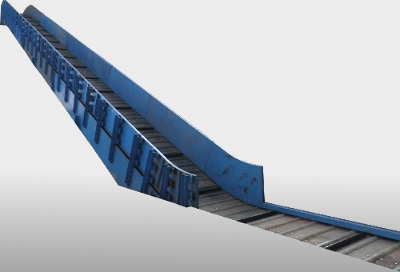

Slat conveyors are mechanical systems designed to transport materials across different elevations and distances. They utilize slats—rigid plates made of metal or plastic—attached to a chain or belt, allowing for the movement of heavy loads. This design is particularly advantageous for industries requiring the transportation of goods that are bulky, irregularly shaped, or packaged.

Why Use Technolink Slat Conveyors ?

1.Robust Construction: Technolink slat conveyors are built to endure demanding environments. Their sturdy construction ensures they can handle heavy loads, making them ideal for industries such as manufacturing, automotive, and food processing.

2.Versatile Applications: One of the primary reasons businesses in India choose Technolink is the versatility of their slat conveyors. These systems can be customized to accommodate various materials and operational requirements, providing a tailored solution that meets specific industry needs.

3.Enhanced Efficiency: Technolink slat conveyors are designed for continuous operation, which minimizes downtime and maximizes productivity. Their smooth operation ensures that materials are transported quickly and reliably, contributing to streamlined workflows.

4.Space Optimization: These conveyors can be configured to operate in limited spaces, allowing businesses to maximize their facility layouts without sacrificing efficiency. The ability to navigate tight corners and inclines makes Technolink slat conveyors particularly effective in compact industrial settings.

5.Safety Features: Safety is a top priority in any industrial operation. Technolink slat conveyors come equipped with essential safety features, such as emergency stop buttons and protective guards, ensuring a secure working environment for employees.

Applications of Technolink Slat Conveyors in India

Technolink slat conveyors are utilized across various sectors due to their adaptability and reliability:

- Automotive Industry: In the automotive sector, slat conveyors facilitate the assembly of vehicles by efficiently transporting parts along the production line. This helps streamline operations and improve production rates.

- Food and Beverage: Technolink slat conveyors are ideal for moving packaged food items through different stages of processing and packaging. Their robust design adheres to hygiene standards, making them suitable for the food industry.

- Pharmaceuticals: In pharmaceutical manufacturing, slat conveyors are used to transport sensitive products while maintaining compliance with regulatory requirements, ensuring the safety and efficacy of the final products.

- Packaging: These conveyors play a critical role in packaging operations, moving items seamlessly from one stage to another, thereby enhancing overall efficiency.

- Manufacturing: In manufacturing environments, Technolink slat conveyors are essential for the transport of heavy machinery and components, improving workflow and reducing manual handling.

Conclusion

In conclusion, Technolink slat conveyors represent a significant advancement in material handling solutions in India. Their robust construction, versatility, efficiency, and safety features make them indispensable across various industries. As businesses aim to enhance productivity and streamline operations, the adoption of Technolink slat conveyors proves to be a strategic investment. By choosing Technolink, companies can ensure they have a reliable and efficient material handling system that meets their unique operational needs, positioning them for success in an ever-evolving marketplace.